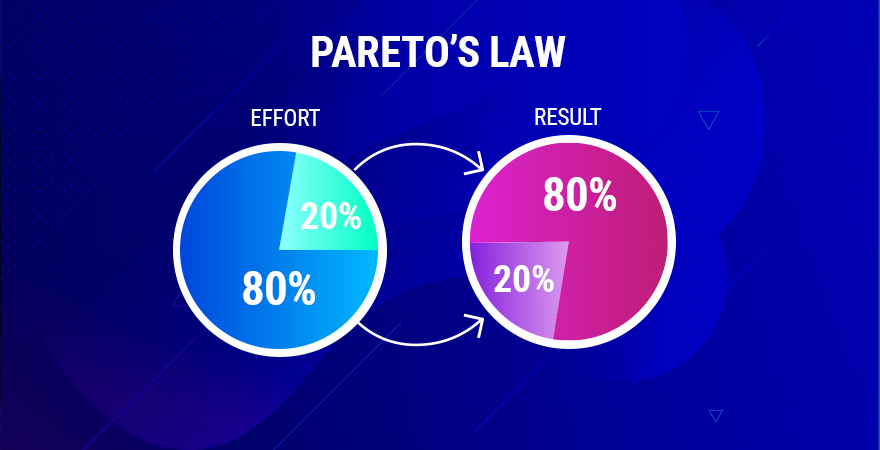

Known by multiple names such as the Pareto Principle, the 80/20 rule, and the law of the vital few and trivial many; Pareto Analysis is a strategic technique applied to logically identify the cumulative impact of a problem stemming from its frequency and multiple causes. One of the Lean Six Sigma methodologies for Process Improvement; Pareto defines that 80% of problems in any process can be effectively managed by addressing 20% of the factors causing it. Utilized for many business applications, especially Quality Assurance metrics, it allows to constantly identify the highest problem driver, and address them in a focused manner to improve the overall procedure.

This principle can be applied across multiple circumstances as a decision-making tool, provided significant data is available to evaluate in a given time frame. For example:

20% of your products/services generate 80% of your profits

80% of Customer complaints come from 20% of service issues

20% of viruses cause 80% of system crashes/errors

80% of a company’s revenue comes from 20% of its clients.

The 80/20 principle is not fixed, rather is a generic number to determine the few most impactful driving factors for Root Cause Analysis, allowing you to prioritize problem-solving. If you see a flat curve (sixsigmastudyguide.com) or no main 2 or three drivers to work on, then either data is lacking, requires re-categorization, or is not showing the right driver first.

Why Use PARETO

It helps prioritize problem-solving for root causes by process of elimination in descending order of impact (cannot be used to determine root cause)

Helps organize pre-existing data to make it more meaningful (softwaretestinghelp.com) (does not apply to future scenarios)

Allows you to address major issues before they can grow in proportion (relatively compares data values)

Improves efficiency, quality of work, and decision making

Quickly helps identify troubleshooting areas for change management

Background and Methodology of Pareto Analysis

The process is named after the Italian economist and strategist, Vilfredo Pareto, who applied the same 80/20 theory to the uneven distribution of wealth in Italy in 1897. Further worked upon by Joseph Juran in the 1940’s it was expanded to the “vital few” and “trivial many” law, which could be applied to other fields as well, ensuring Quality Engineering. The vital few identify the most pressing concerns that should be immediately concentrated upon, while the trivial many have lower impact, and thus, can be prioritized for later.

Represented in the form of a Pareto chart (dual bar and line graph), it presents an overview of problems in descending order, with each assigned a numerical value to determine the percentage of impact. To create a Pareto chart, you need to go through several steps which are as follows: –

Identify, list, and define all the problems that need to be addressed regarding a particular service. (e.g. Customer Services feedback errors: call-waiting, language-barrier, the problem not resolved, response time, etc.)

Decide by quantity, cost, measurement, the time frame of data used, and frequency to group problem items on the x-axis

Plot the frequencies on the y – axis by scoring each group for a fixed time cycle of observations (data from 3 or 6 months in bar graphs with the highest first)

Calculate and plot cumulative percentages line/curve of each occurrence (% in another y-axis on the right)

Find the cross-reference point from the 80% mark on the y-axis to the point intersecting with the x-axis, dropping a vertical line. This will help separate the “vital few” of the issues from the “trivial many” of the issues.

Now you know which defects are the highest drivers and need to be tackled first.

Premier BPO’s Process Improvement with PARETO Analysis

Premier BPO uses Pareto Analysis for customized, Business Intelligent solutions for our clientele. Using this methodology, we timely identify root causes for defects to effectively mitigate them. This allows us to improve overall procedural quality at a very high pace by focusing our efforts on the few instances that require the most attention, yet yield the highest results.

Our extensive QA management team takes the results of the analysis and generates cost-effective and expedited solutions. In every cycle, a new set of defects is identified, allowing us to address quality systemically, quickly, and recurrently. We deep dive into data collected to find disparity and direct our efforts on the top few highest occurring pain points. Streamlining procedures to improve overall performance, we can also provide insight for Business Analytics using Pareto.

Premier BPO utilizes global labor arbitrage for cost-effective, right-shored solutions; creating a perfect blend of technology and manpower with best industry practices. To know more about our service range, visit our website.

Skip to content

Skip to content